Rust is an inevitable adversary in the world of metal maintenance. As moisture and oxygen interact with metal surfaces, corrosion occurs, leading to structural damage, aesthetic degradation, and costly repairs. Traditional rust removal methods, such as sandblasting and chemical treatments, often pose challenges, including environmental concerns and potential harm to the underlying material. However, advancements in laser technology have given rise to a new solution: laser rust removal machines. This article explores the features, benefits, applications, and availability of these machines, highlighting LASERCLEANER’s commitment to innovation and quality.

What is a Laser Rust Removal Machine?

A laser rust removal machine employs focused laser beams to efficiently remove rust and other contaminants from metal surfaces. The high-intensity laser light vaporizes or dislodges rust without damaging the underlying material, providing a clean, smooth surface ready for further processing or protection. This non-contact method is transforming how industries approach rust removal.

Benefits of Laser Rust Removal Machines

Non-Destructive Cleaning: One of the standout features of laser rust removal is its non-destructive nature. Unlike abrasive methods that can scratch or alter the metal surface, laser technology ensures the integrity of the substrate is maintained. This is particularly important for high-value components and delicate machinery.

Environmentally Friendly: As environmental concerns continue to rise, the need for eco-friendly cleaning solutions has become paramount. Laser rust removal machines do not rely on harsh chemicals, making them a safer option for both workers and the environment. The process generates minimal waste, contributing to a cleaner workspace.

Speed and Efficiency: Time is money in any industry, and laser rust removal machines excel in efficiency. They can quickly remove layers of rust in a single pass, significantly reducing downtime. This speed translates to improved productivity and a faster turnaround for maintenance tasks.

Precision Control: Laser technology offers unparalleled precision. Operators can adjust the laser's intensity and focus, allowing for targeted cleaning that preserves intricate details on components. This level of control is crucial in industries where maintaining the integrity of the metal is paramount.

Cost-Effective: While the initial investment in a laser rust removal machine may seem high, the long-term savings can be significant. Reduced labor costs, lower material waste, and increased productivity contribute to an overall decrease in maintenance expenses.

Versatility Across Industries: Laser rust removal machines can be used on a variety of metals, including steel, aluminum, and copper. Their versatility makes them suitable for a wide range of applications, from automotive to marine and industrial sectors.

Key Features to Look for in a Laser Rust Removal Machine

Laser Type:

- Fiber Lasers: Known for their efficiency and power, fiber lasers are ideal for industrial applications requiring robust cleaning performance.

- CO2 Lasers: While typically more affordable, CO2 lasers can be less effective on certain metal surfaces, making it essential to choose the right type based on your specific needs.

Power Output: The power output of the laser significantly impacts its performance. Higher wattage means quicker cleaning, making it an essential factor when selecting a machine.

User-Friendly Interface: A machine with an intuitive control panel simplifies the operation. Look for models that offer programmable settings, allowing for easy adjustments and automation of cleaning tasks.

Safety Features: Safety is crucial when operating any machinery. High-quality laser rust removal machines come equipped with safety features, such as protective enclosures, automatic shutoff functions, and safety glasses to protect operators from laser exposure.

Portability: Depending on your application, portability might be a significant factor. Portable laser rust removal machines offer flexibility, allowing you to take the cleaning solution directly to the job site.

Applications of Laser Rust Removal Machines

Industrial Maintenance: Regular maintenance is vital to keep machinery operating efficiently. Laser rust removal machines excel in restoring the surfaces of equipment, preventing further corrosion and extending their lifespan.

Automotive Sector: In the automotive industry, laser cleaning is used for surface preparation before painting or coating. It effectively removes rust and contaminants, ensuring optimal adhesion and finish quality.

Marine Industry: Ships and offshore structures are prone to rust due to exposure to moisture and salt. Laser rust removal offers an effective solution to maintain the integrity and appearance of these assets.

Construction Equipment: Heavy machinery used in construction is often exposed to harsh conditions. Laser rust removal helps in maintaining the equipment, reducing the risk of structural failure and ensuring safety.

Restoration Projects: For restoration experts working on historical artifacts or vehicles, laser rust removal provides a gentle yet effective method to clean without damaging the original materials.

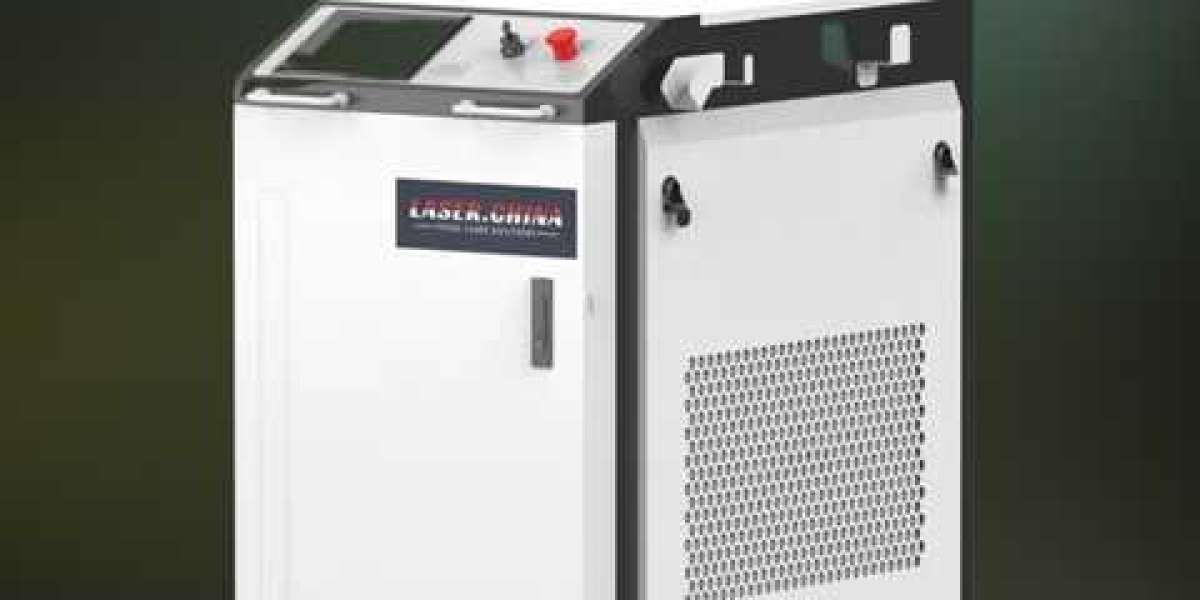

Purchasing Laser Rust Removal Machines from LASERCLEANER

LASERCLEANER is dedicated to providing high-quality laser rust removal machines that meet the demands of various industries. Our machines come equipped with advanced features designed to enhance performance and ensure user safety. We pride ourselves on delivering reliable products that help businesses operate efficiently and sustainably.

When considering a purchase, our team at LASERCLEANER is ready to assist with personalized consultations, helping you find the right machine tailored to your specific needs. With competitive pricing and robust warranties, investing in a laser rust removal machine from LASERCLEANER is a step toward future-proofing your maintenance operations.

Conclusion

As industries face the ongoing challenge of rust and corrosion, laser rust removal machines offer a forward-thinking solution that combines efficiency, precision, and environmental sustainability. With LASERCLEANER leading the way, businesses can take advantage of this innovative technology to streamline their cleaning processes and enhance their maintenance practices. Investing in a laser rust removal machine is not just a purchase; it’s a commitment to quality, safety, and sustainability in an ever-evolving industrial landscape.